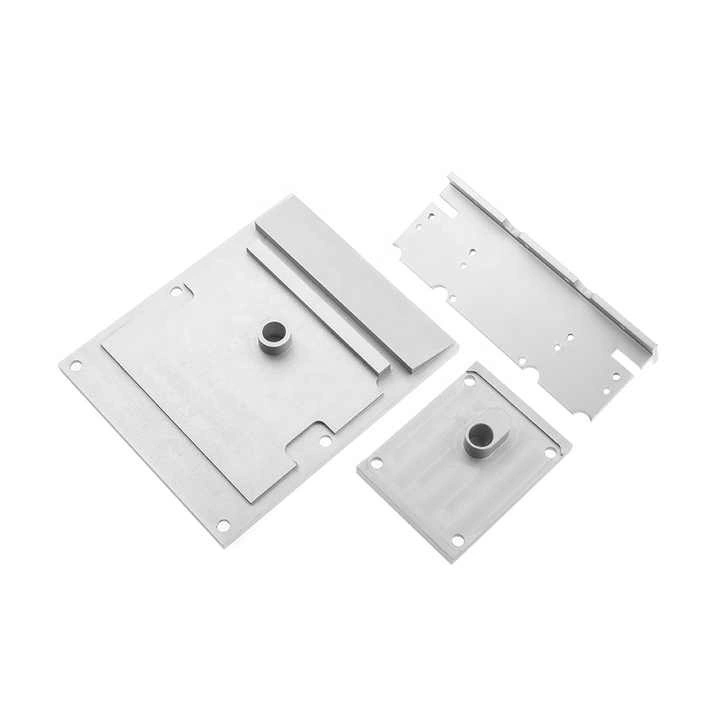

Precision CNC ring milling aluminum parts

Material: Aluminum alloy

Size: Customized

Process: CNC turning, Milling, sheet metal machining, die casting

Surface treatment: polishing, drawing, oxidation, painting, electroplating

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

Product Advantages:

High precision: CNC ring machining milling enables extremely high machining accuracy, often achieving dimensional accuracy of ±0.01mm or more, as well as form accuracy of less than 0.005mm. This allows the machined aluminum ring parts to perfectly meet a variety of stringent assembly requirements, ensuring the overall performance and reliability of the product.

Complex Shape Machining Capability: With the flexibility of CNC technology, the process can easily machine a variety of complex ring shapes, including parts with features such as concave, convex, curved profiles, shaped holes, and more. Whether it is a simple round ring or a non-standard ring with complex geometries, it can be achieved with precise programming and milling, providing greater freedom in product design.

Good surface quality: During the milling process, a very smooth surface quality can be obtained by reasonably selecting the process parameters such as tool parameters, cutting speed, and feed. Under normal circumstances, the surface roughness of processed aluminum parts can be controlled between Ra0.8-Ra1.6μm, and some occasions with higher requirements can even achieve the mirror effect of Ra0.2-Ra0.4μm, which reduces the workload of subsequent surface treatment and improves the appearance quality and corrosion resistance of the product.

High Material Utilization: CNC milling is a subtractive machining process, but it minimizes material waste due to its precise control capabilities. When processing annular parts, it can be accurately cut according to the actual shape and size of the parts, so that the utilization rate of raw materials has been significantly improved, the production cost has been reduced, and it also meets the requirements of modern manufacturing industry for resource conservation and environmental protection.

High production efficiency: Once the CNC program is written and debugged, the machine can automatically carry out mass production without too much manual intervention, which greatly improves production efficiency. Moreover, CNC machine tools have high cutting speed and feed speed, which can complete the milling of aluminum parts in a short time, shorten the production cycle of products, and help to quickly respond to market demand

Send Inquiry