About RUIRUI

Qingdao Ruirui Machinery Manufacturing Co., Ltd. was established in 2008 in Qingdao, China, specializing in the research and development, production and sales of sheet metal parts, stamping parts and other metal parts.

With more than 17 years of successful management and production experience, our products are exported to more than 80 countries and regions at home and abroad, especially exported to Spain, the United Kingdom and many other European regions, Canada, the United States, Brazil and Australia.

The company has established a fully automatic robot production line with an annual output of 130,000 pieces and a thermoplastic spraying process line. It has advanced machines and multiple production lines such as welding, bending, laser, spraying, etc.

-

Year Experience

17+

-

Production Lines

06

-

Cover Area

3000+m2

-

annual production capacity

80

-

Customer Services

24h

-

Exported Countries

80

1

Production process

2

Production Materials

3

Quality Assurance

Heavy Duty Snatch Block

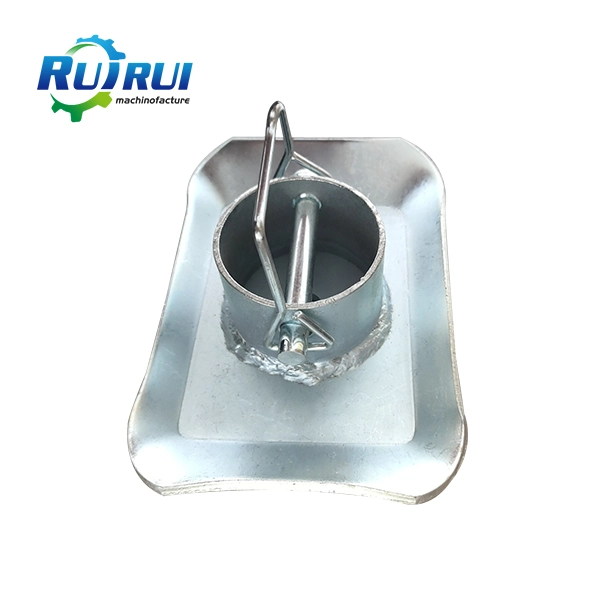

Trailer Jack Foot Plate

Steel trailer fender

Upright support bracket

Coupler Repair Kit For 2"

Trailer Jack With Dual Wheels

Trailer Hitch Ball Mount

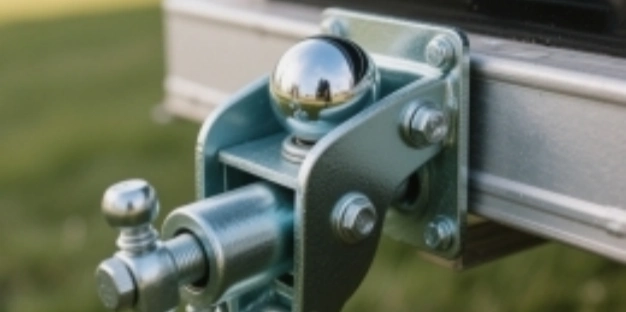

Trailer Ball Coupler

Trailer ball cover connector

High Quality Trailer Ball Cover

3.5T Caravan Coupling

High quality trailer couplings

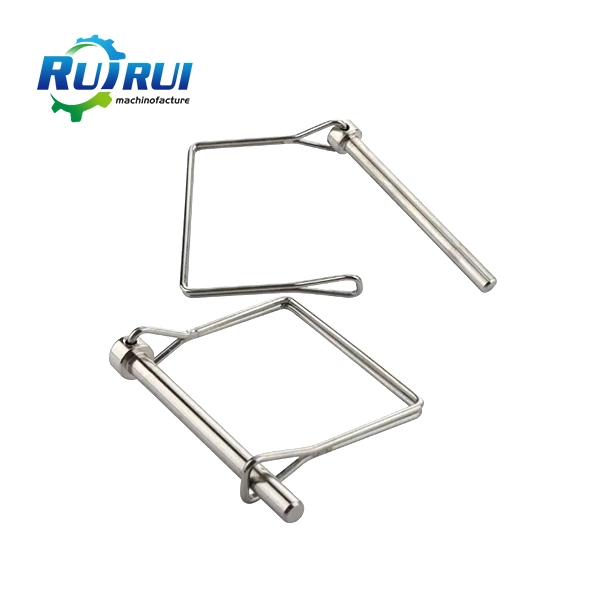

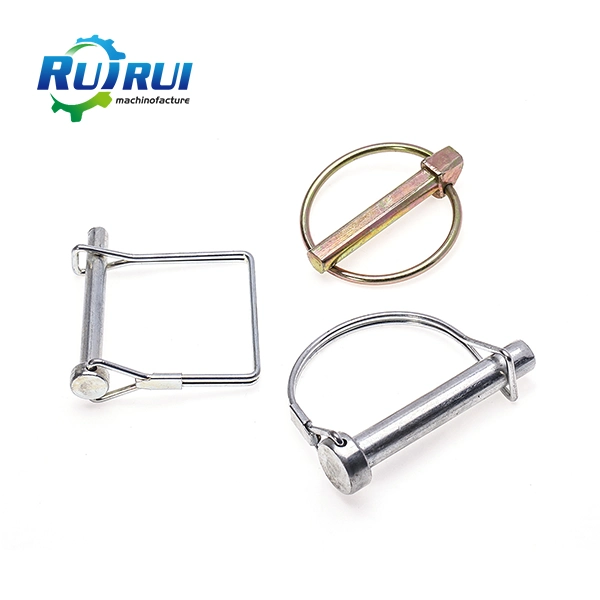

Trailer Connector

Receiver Hitch D Ring Shackle

Lifting Chain Slings

snatch block

1-7/8" Trailer Balls

Trailer Hitch Ball Mount

Ask for quotation

Be A High-Quality & Stable Supplier Provide Sincere & Reliable Customized Services

Contact usBlog

Location Details

- Address: No. 12, Wenyuan Road, Xinjiazhuang Industrial Park, Jimo, Qingdao, Shandong Province, China

Tel: +86 13070876125

Whatsapp: +86 13070876125

Email: kshdhardware@qdkshd.com