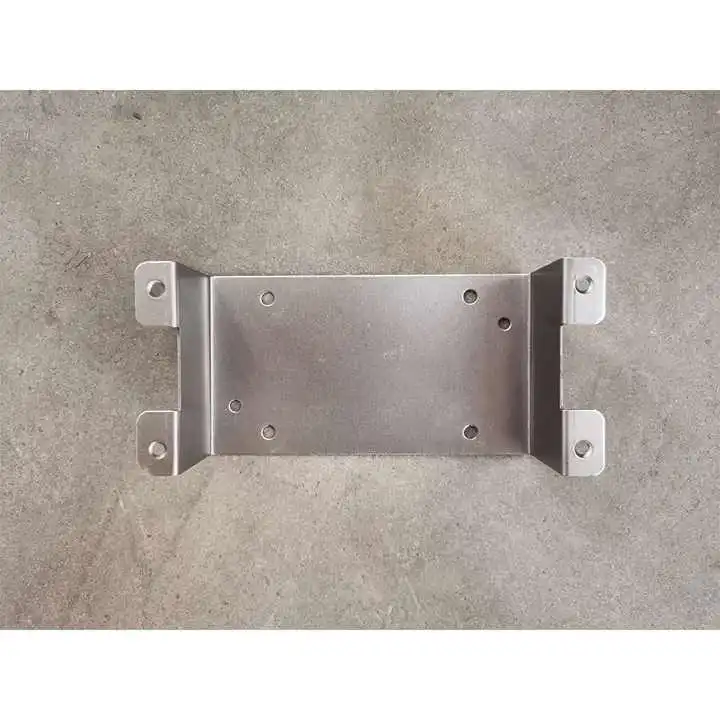

High precision custom CNC bending parts

Service: OEM ODM customization

Equipment: bending, stamping, cutting machines

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

(1) Strict inspection of raw materials

When purchasing raw materials, each batch of metal sheets is strictly inspected, including the chemical composition, mechanical properties, surface quality and other aspects of the material. Only raw materials that meet high quality standards will enter the production process to ensure the quality of electronic shell parts from the source.

(2) Process monitoring

Every production step of stamping and bending is monitored in real time by professionals. Through advanced monitoring equipment, pay close attention to the equipment operating parameters, mold status, machining accuracy, etc., and find and solve possible problems in time.

Regularly maintain and maintain the production equipment to ensure that the equipment is in the best operating condition, so as to ensure the stability of the processing process and the consistency of product quality.

(3) Finished product testing

A variety of testing methods, such as coordinate measuring instrument, profilometer, hardness tester, etc., are used to comprehensively detect the finished electronic shell parts. The inspection content covers dimensional accuracy, shape accuracy, surface quality, structural strength and other aspects to ensure that every product delivered to customers meets or even exceeds industry standards.

Products that fail to pass the test are resolutely not shipped from the factory, but are reworked or scrapped to maintain the reputation of high quality of our services.

Send Inquiry