What is the difference between link plates and other types of connectors?

2024-09-27 10:24:01

In the world of urban furniture and structural engineering, various connectors play crucial roles in joining different components securely. Among these, link plates have emerged as a popular choice for many applications. This blog post delves into the unique characteristics of it and how they differ from other types of connectors. We'll explore their design, functionality, and advantages, comparing them to alternative connection methods. Whether you're involved in construction, manufacturing, or simply curious about urban infrastructure, understanding these differences can provide valuable insights into the engineering choices that shape our built environment.

Understanding Link Plates and Their Unique Features

The Anatomy of a Link Plate

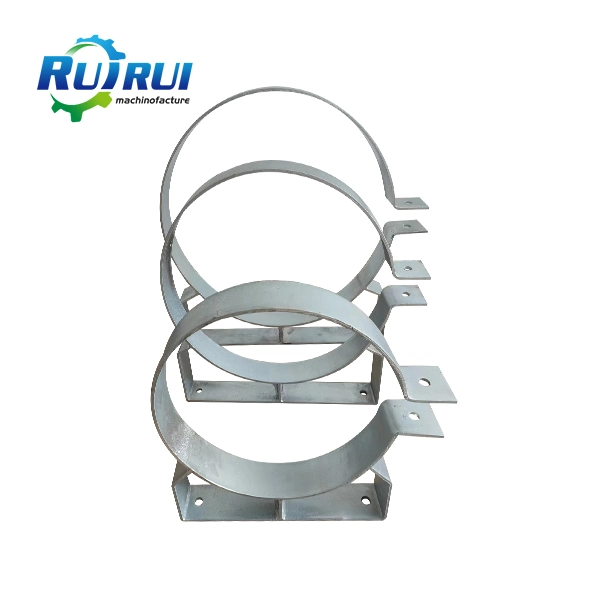

Link plates are specialized connectors designed to join structural elements efficiently and securely. These plates are typically made from high-strength materials such as galvanized steel or stainless steel, ensuring durability and resistance to corrosion. The design of a link plate often includes multiple holes or slots, allowing for versatile attachment options. This unique configuration enables it to distribute loads evenly across connected components, reducing stress concentrations and enhancing overall structural integrity.

Key Advantages of Link Plates

One of the primary advantages of it is their ability to provide a strong, yet flexible connection. This flexibility allows for slight movements or adjustments in the connected elements, which can be crucial in structures subject to dynamic loads or environmental factors. Additionally, link plates often offer superior load-bearing capacity compared to many other connector types, making them ideal for heavy-duty applications. Their flat profile also contributes to a sleek appearance, which can be particularly beneficial in visible urban furniture installations.

Applications of Link Plates in Urban Furniture

In the context of urban furniture, it find extensive use in various applications. They are commonly employed in the assembly of benches, where they connect seat panels to support structures. Link plates also play a vital role in the installation of bicycle racks, providing secure attachment points between the rack and the ground or wall. Their versatility extends to the construction of modular outdoor tables and chairs, where they facilitate easy assembly and disassembly for maintenance or reconfiguration.

Comparing Link Plates to Other Connector Types

Link Plates vs. Welded Connections

While welded connections offer exceptional strength, they lack the flexibility and adjustability provided by it. Welding is a permanent joining method, making future modifications or repairs challenging. In contrast, link plates allow for easier disassembly and reassembly, which can be advantageous in scenarios where urban furniture needs to be relocated or reconfigured. Moreover, link plates eliminate the need for specialized welding equipment and skilled welders on-site, potentially reducing installation costs and time.

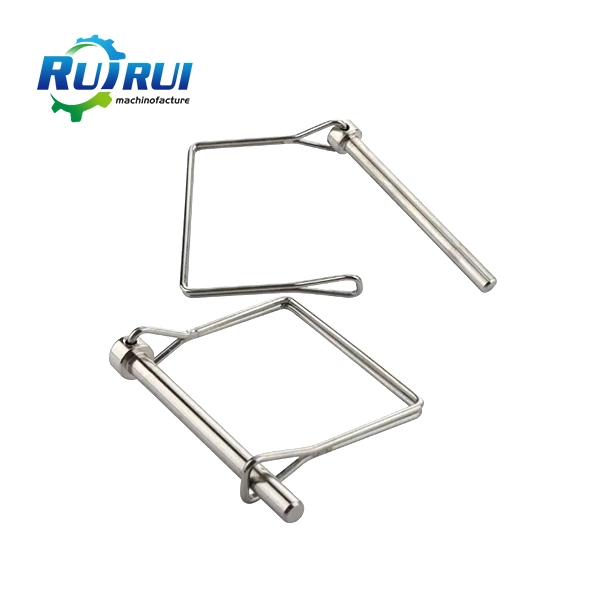

Link Plates vs. Bolted Connections

Bolted connections share some similarities with link plates, as both utilize fasteners for joining components. However, it often provide a more distributed load transfer compared to simple bolted joints. The design of it allows for multiple attachment points, which can enhance the overall stability of the connection. Additionally, link plates can be engineered to accommodate slight misalignments during assembly, a feature not typically available with standard bolted connections.

Link Plates vs. Adhesive Bonding

Adhesive bonding is another method used in some urban furniture applications, particularly for joining dissimilar materials. While adhesives can provide a clean, seamless appearance, they may not match the strength and durability of it in high-stress applications. Link plates offer the advantage of mechanical fastening, which is generally more reliable in outdoor environments subject to temperature fluctuations and moisture exposure. Furthermore, connections made with link plates are more easily inspected and maintained compared to adhesive bonds.

Factors Influencing the Choice Between Link Plates and Other Connectors

Load-Bearing Requirements

The choice between link plates and other connector types often hinges on the specific load-bearing requirements of the application. Link plates excel in scenarios where high loads need to be distributed across a connection interface. Their ability to spread forces over a larger area makes them particularly suitable for heavy-duty urban furniture installations, such as robust park benches or large-scale public art structures. In contrast, lighter-duty applications might be adequately served by simpler connector types, where the full strength of a link plate is not necessary.

Environmental Considerations

The environmental conditions in which urban furniture will be placed play a significant role in connector selection. Link plates, especially those made from corrosion-resistant materials like stainless steel, offer excellent durability in outdoor settings. They can withstand exposure to rain, snow, and temperature fluctuations better than many alternative connection methods. This resilience makes link plates a preferred choice for coastal areas or locations with harsh weather conditions. However, in protected indoor environments, other connector types might suffice and potentially offer cost savings.

Aesthetic and Design Factors

The visual impact of connectors is an important consideration in urban furniture design. It can be engineered to provide a sleek, modern appearance that complements contemporary architectural styles. Their low profile and ability to be partially concealed within the structure make them less obtrusive than some other connector types. This aesthetic advantage must be weighed against the design goals of the project. In some cases, exposed bolts or decorative welded joints might be preferred for their industrial or artisanal look, despite the functional benefits of it.

Conclusion

Link plates offer a unique combination of strength, flexibility, and aesthetic appeal that sets them apart from other connector types in urban furniture applications. Their ability to distribute loads effectively, coupled with ease of installation and maintenance, makes them a versatile choice for many projects. While other connectors may be suitable in specific scenarios, the overall advantages of link plates often make them the preferred option for durable, high-quality urban furniture installations. If you want to get more information about this product, you can contact us at info@qdkshd.com.

References

1. Smith, J. (2022). "Connector Types in Urban Furniture Design: A Comprehensive Guide"

2. Johnson, A. & Lee, M. (2021). "Link Plates: Engineering Solutions for Modern Structures"

3. Urban Design Institute. (2023). "Comparative Analysis of Structural Connectors in Public Spaces"

4. Brown, R. (2020). "Material Science in Urban Infrastructure: From Bolts to Link Plates"

5. Zhang, L. et al. (2022). "Load Distribution Characteristics of Various Connector Types in Modular Furniture"

6. European Association of Urban Planners. (2023). "Best Practices in Urban Furniture Connection Methods"

Send Inquiry

Related Industry Knowledge

- What Are the Different Types of Bollards?

- What Are U Bolts Used For?

- What is a Mounting Bracket?

- What is a pump cover plate?

- How do link plates contribute to structural integrity?

- How do you install a link plate?

- What materials are used for street furniture?

- What materials are link plates made from?

- What are the different types of bollards?

- What is a link plate used for?